Top Quality Digitizing for Embroidery: Specialist Craftsmanship

Top Quality Digitizing for Embroidery: Specialist Craftsmanship

Blog Article

Understanding the Embroidery Digitizing Process: Your Ultimate Guide

Embroidery digitizing is a careful craft that requires accuracy and experience to convert complex designs into electronic layouts for equipment needlework. As craftsmens start this journey to master the embroidery digitizing procedure, a detailed understanding of the essentials establishes the structure for quality. Past the simple understanding exists a realm of advanced software application, specialized tools, and nuanced methods waiting to be discovered. By delving into the nuances of digitizing, one can open a world of imaginative possibilities and boost their embroidery jobs to new elevations.

Understanding Embroidery Digitizing Basics

Embroidery digitizing fundamentals create the structure whereupon detailed layouts are converted right into machine-readable layouts for specific sewing. This first action in the needlework digitizing procedure is vital for ensuring that the final stitched item is a loyal depiction of the initial style. Comprehending embroidery digitizing fundamentals involves understanding essential ideas such as stitch types, sew instructions, thickness, padding, and draw payment.

Stitch kinds play an essential duty in establishing the aesthetic and textural result of the embroidered design. By selecting the ideal stitch kind, whether it be satin, fill, or running stitch, digitizers can attain the wanted effect and boost the general quality of the needlework. In addition, stitch instructions affects the flow and dimension of the design, while thickness identifies the spacing and insurance coverage of the stitches.

In addition, rug stitching gives stability to the design by safeguarding the fabric and preventing distortion throughout the embroidery process. Draw compensation is an additional vital consideration to combat the natural propensity of fabric to agreement when stitched. Grasping these needlework digitizing fundamentals is basic for producing professional-quality embroidered products.

Choosing the Right Digitizing Software Application

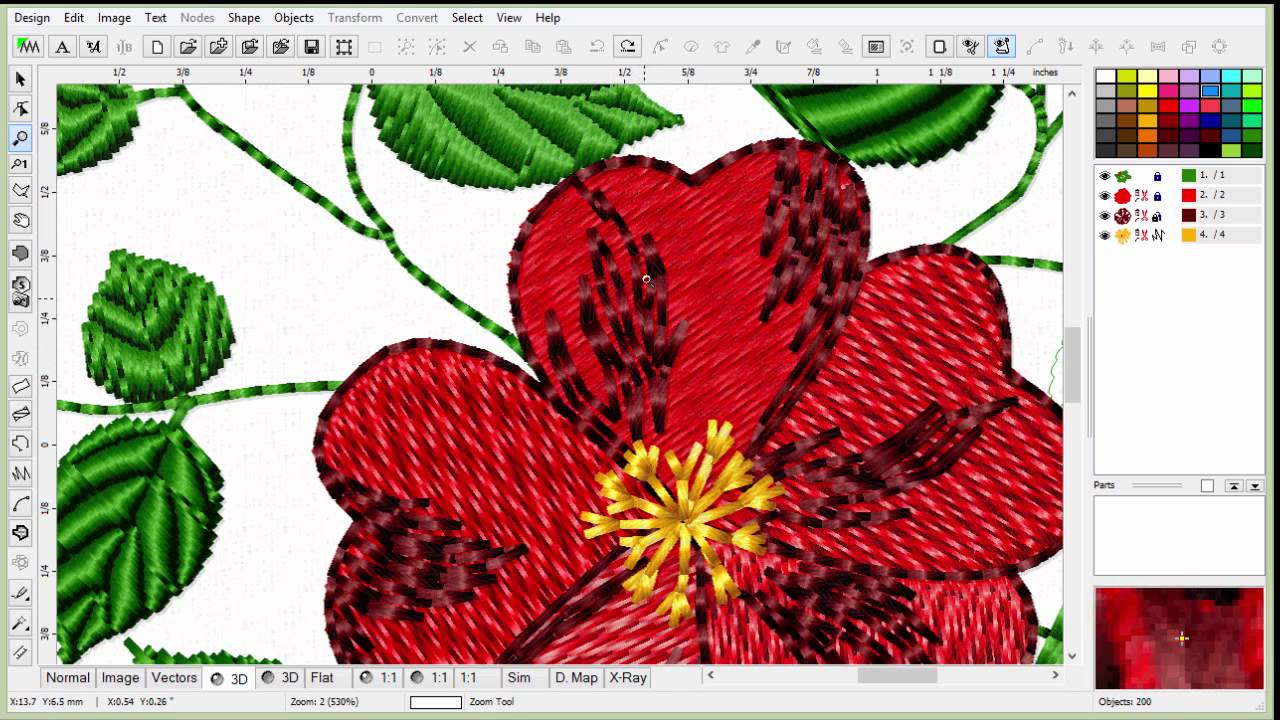

Choosing the suitable digitizing software application is an important decision that dramatically affects the performance and top quality of the embroidery digitizing procedure. Digitizing for Embroidery. When selecting the appropriate digitizing software application, it is vital to think about variables such as the complexity of layouts you plan to develop, the user-friendliness of the software, the degree of customer assistance used, and the compatibility with your needlework maker

There are different digitizing software program alternatives offered on the market, varying from fundamental programs for beginners to sophisticated software for specialist digitizers. Some popular selections include Wilcom EmbroideryStudio, Hatch Embroidery Software, and PulseID. These software bundles provide a large range of devices and functions to aid you develop elaborate layouts with convenience.

Before deciding, it is advisable to check out the different software application options through free tests or demonstrations to identify which one best matches your demands. Furthermore, reading reviews and looking for recommendations from experienced digitizers can provide beneficial insights into the toughness and weaknesses of each software plan (Digitizing for Embroidery). By very carefully read review assessing your requirements and contrasting the functions of various digitizing software program, you can make an informed selection that enhances your needlework digitizing process

Digitizing Tools and Methods

Optimizing Style Setup for Embroidery

Grasping the complexities of style settings is essential in attaining ideal cause the embroidery digitizing process, building upon the foundation laid by comprehending digitizing tools and methods. When optimizing style setups for needlework, it is important to consider aspects such as stitch type, density, underlay, pull compensation, and registration. Sew look at this web-site type option affects the general feel and look of the style, with options like satin, fill, and running stitches offering different structures and impacts. Thickness describes the spacing and density of stitches, influencing the design's insurance coverage and longevity. Appropriate rug stitching supplies security and stops material distortion, especially for complicated styles or on elastic materials. Pull compensation readjusts for fabric stretch throughout stitching, guaranteeing exact style duplication. Registration setups align various elements of the layout properly, maintaining total design honesty. By fine-tuning these design setups, embroiderers can enhance the top quality and precision of their stitched creations.

Troubleshooting Common Digitizing Issues

When running into common digitizing concerns throughout the needlework procedure, it is necessary to understand the origin creates and execute reliable services immediately. One common issue is stitch thickness concerns, where stitches may be as well thick, causing the material to tighten, or too sparse, causing voids in the design. Readjusting the stitch density settings in the digitizing software application can help fix this problem.

An additional constant challenge is thread breaks during the embroidery process. This can happen as a result of numerous reasons such as incorrect tension setups, dull needles, or using low-quality string. Making certain correct upkeep of the needlework machine, including regular needle changes and tension modifications, can lessen the event of string breaks.

In addition, design registration errors can result in misaligned components Discover More Here within the needlework layout. Examining the layout placement in the digitizing software program and making necessary adjustments prior to sewing can aid in preventing this problem. By attending to these typical digitizing problems quickly and efficiently, you can guarantee a smoother embroidery process and premium completed products.

Conclusion

To conclude, understanding the needlework digitizing process needs a solid understanding of the basics, the right selection of software program, and expertise of tools and techniques. Maximizing style settings and troubleshooting usual digitizing concerns are crucial action in making sure top notch embroidery outcomes. By complying with these steps faithfully, one can accomplish precision and performance in the digitizing process.

Report this page